The Huletts were revolutionary automatic ore unloaders, huge mechanical materials handling machines designed specifically for use at the Great Lakes of North America. Their unsuitability for use in tidewater ports, as they could not adjust to rising and falling water levels, meant that they were rarely used elsewhere.

The innovator responsible for designing these automatic unloaders is George Hulett of Ohio. Patented in 1898, the first of his machines was built the following year in 1890 at Conneaut Harbor in Conneaut, Ohio. It was the Webster, Camp & Lane Company of Akron that did the initial construction.

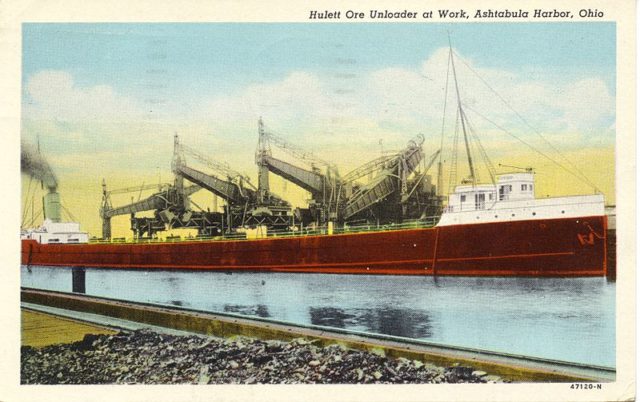

This first generation of Hulett proved to be a success and many more were soon built along the Great Lakes, most notably the southern shore of Lake Erie. Here this machine was used to unload boats full of taconite from the iron mines near Lake Superior.

As time went on, Samuel T. Wellman made some substantial and necessary improvements to the original design. The last Huletts to remain standing were from this second generation.

The Hulett machines more than revolutionized iron ore shipment on the Great Lakes. The cost for emptying a lake freighter using buckets, hoists, and much hand labor was approximately 18¢/ton. The same job was done by a Hulett at a price of 5¢/ton and this 13¢ difference made the machines so popular that they appeared in numerous articles and newspapers.

The mechanised process could take anywhere between 5 to 10 hours. In comparison, the previous method of unloading by hand could take a whole week. This faster unloading allowed for ships to become larger, doubling in length and quadrupling in capacity.

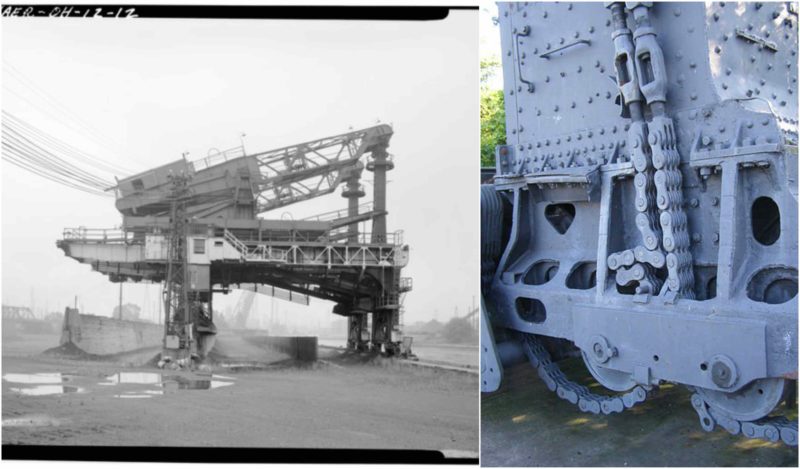

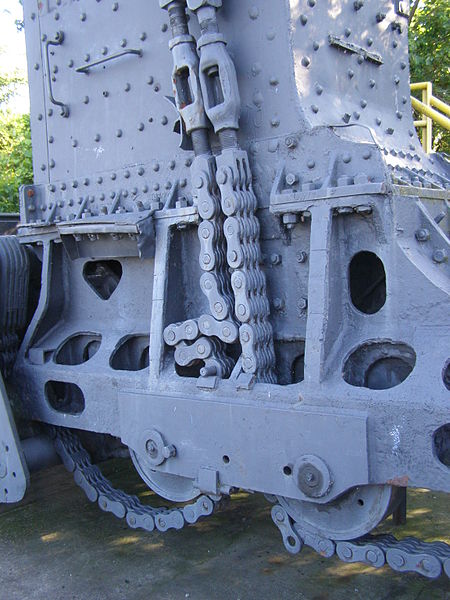

The Huletts were electrically powered and rode on two parallel tracks along the docks. The “bucket car”, a carriage from which extended a beam that could be moved up and down with the huge bucket at the end, ran along a girder supported by steel towers. These towers rode along the dock railroad tracks on wheeled trucks.

Even though the Huletts were automatic, the human factor in this whole equation was not excluded. When the hold was mostly empty, it was the job of the “Ore Hogs” to jump in and assist this metal giant. These workmen entered the hold and shovelled the remaining ore into the Hulett’s bucket. As of more recent times, a wheeled excavator would be chained to the Hulett’s bucket and lowered into the hold to fill the Hulett.

As their popularity grew, by 1913 there were around 54 Hulett machines installed. Two were installed at Lake Superior for unloading coal and five at Gary, Indiana, but the majority of the machines were along the shores of Lake Erie. Among the most notable ports where Hulett unloaders were installed are the ports at Ashtabula, Cleveland, Conneaut, Huron, Lorain, and Toledo.

The additional unloading capacity that the Huletts brought allowed for more than doubling of the ore traffic in the 1900–1912 period. The total number of Huletts installed was around 75. One was even installed in New York to unload garbage.

Huletts were used until 1992 when self-unloading boats became the standard on the American side of the lake. Since then almost all of them have been scraped. By the time the calendar showed 1999 there were only six left, four of them at Whiskey Island in Cleveland, Ohio. The rest were used for unloading barges of coal in South Chicago until 2002.

Last of them were demolished in the Spring of 2010. Even though this machines were part of the National Register of Historic Places and designated as a Historic Mechanical Engineering Landmark they were still dismantled to enable development of the underlying land. Two Huletts were saved from scrap and stored on Whiskey Island for preservation, but have yet to be re-erected.