Located along the Uruguay River is Fray Bentos, a town known for being the manufacturing hub for Fray Bentos corned beef and other meat products that fueled soldiers during the First and Second World Wars. The factory behind the famed canned food is the Frigorífico Anglo del Uruguay – better known by its English name, the Anglo Meat Packing Plant.

Following World War II, the popularity of Fray Bentos corned beef dropped, leading to the eventual closure of the Uruguayan factory and the company moving its operations.

Establishment of Liebig’s Extract of Meat Co.

In the 19th century, German chemist Justus von Liebig invented a “meat tonic,” today known as the bouillon cube. Looking to capitalize on the product, he founded Liebig’s Extract of Meat Co. and set up a cattle processing plant in Uruguay with Georg Gieber, a Belgian engineer.

While von Liebig could have set up shop anywhere, he opted for the site along the Uruguay River because it had its own harbor, meaning he could export his products across the world for cheap and on his own schedule. It was also less expensive to raise cattle in South America, compared to Germany.

In 1873, the factory began producing corned beef under the name Fray Bentos, after the nearby town. The product was geared toward Europe’s working class and quickly became a hit. In fact, there was such a high demand that the factory needed to expand in order to accommodate the number of workers it needed.

Before long, the area around the factory had its own cleaning and garbage services, brick houses, a school, a social club and a hospital. They came together to form the “Barrio Anglo” along the edge of the Uruguay River, which became known as a city-within-a-city.

The operation changes hands

By the beginning of World War I, Fray Bentos products were world-renowned. The company had provided its products to troops during the Boer War and continued to do so during the First World War, with British and German troops known to carry the long-lasting and inexpensive corned beef.

The product was so beloved, in fact, that a tank crew named their Mark IV tank after it. While the vehicle was sadly lost during the Battle of Passchendaele after getting stuck in the mud in No Man’s Land, a second later bore the Fray Bentos name.

In 1924, von Liebig’s factory was purchased by a British firm and renamed the Frigorífico Anglo del Uruguay – the Anglo Meat Packing Plant. It continued to ship products worldwide and was nicknamed “The Great Kitchen of the World.” Its popularity peaked during the Second World War, with over 16 million cans of corned beef delivered to Europe in 1943.

The factory employed 5,000 workers who processed 400 cows every hour and 2,000 sheep each day. While many of its employees were local, they came from across the world, including from Belgium, England, Italy, Russia and Spain.

The company began experiencing troubles following WWII. This was due to a number of factors, including a shift in eating habits and the development of food technology. What really impacted the company was a typhoid outbreak in Aberdeen, Scotland in 1964, which was traced back to a can of corned beef. It was later found to have been contaminated by untreated water during the cooling process.

In the late 1960s, the factory was given to the Uruguayan government and, later, shuttered.

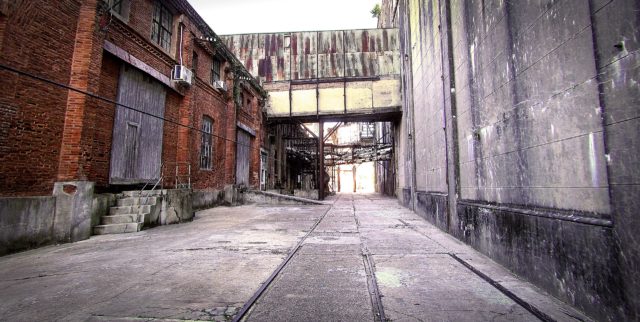

The Anglo Meat Packing Plant today

In 2008, Brazilian food manufacturer Marfrig set up shop at Anglo Meat Packing Plant. It produced corned beef, but did so without the rights to the Fray Bentos company name. Seven years later, the factory was named a UNESCO World Heritage Site.

Today, a portion of the factory is home to the Museo de la Revolución Industrial, which displays artifacts from its heyday. These include preserved Fray Bentos cans, the original machinery, posters, delivery trucks, typewriters, firefighting equipment and photographs showing employees at work.

The museum is open to the public.

More from us: Six Secret and Forgotten Places Beneath the Streets of New York City

Given the factory’s size, it also houses additional businesses. For example, one section has been taken over by a local university. However, the majority of the site has remained as it was when it was abandoned decades ago, showing the wear and tear of disuse and disrepair.